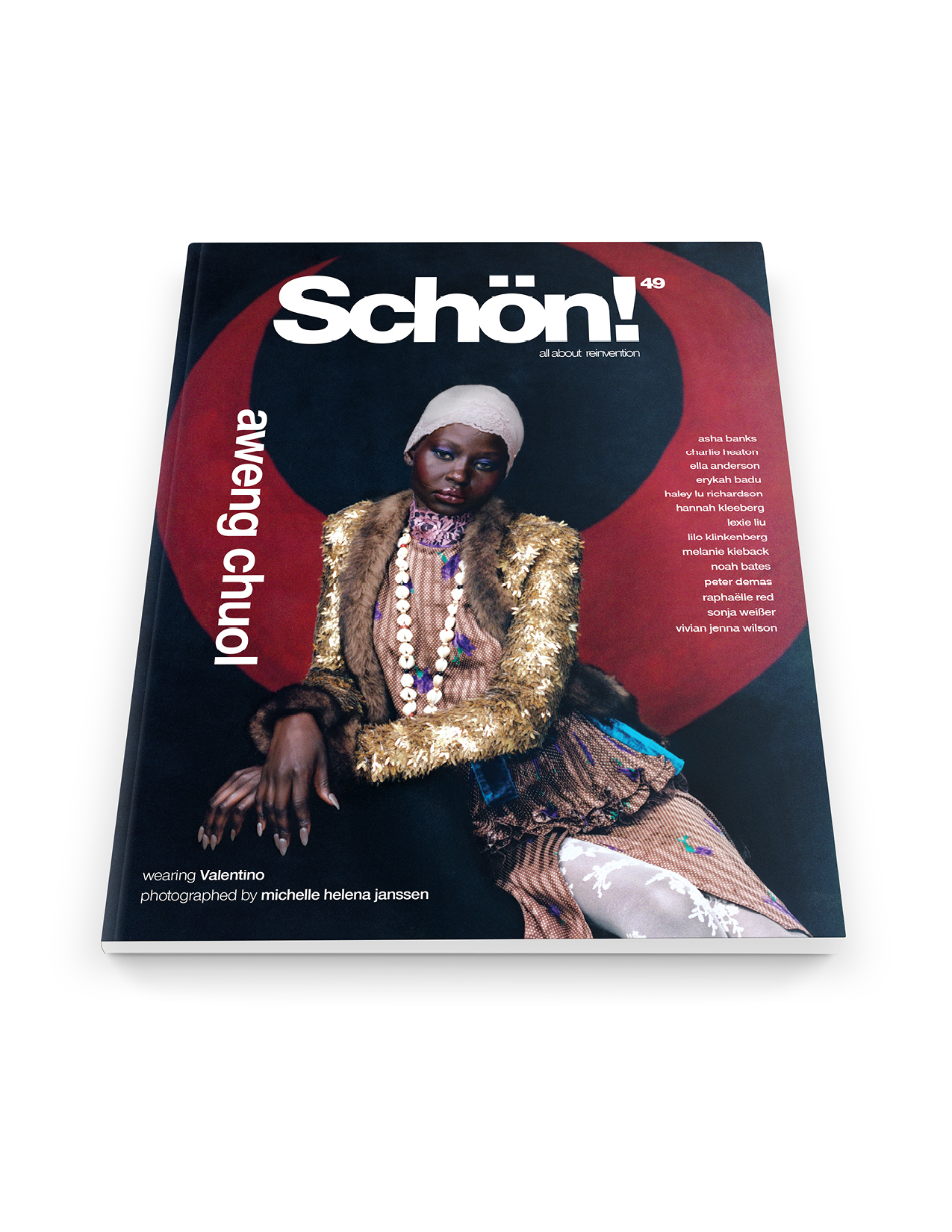

For more than 80 years, Vibram has set the benchmark for high-performance rubber outsoles, becoming a global leader across sport and leisure, becoming a trusted shoe for athletes, adventurers, and designers alike. Vibram’s legacy began in the 1930s when founder Vitale Bramani revolutionized mountaineering with the world’s first rubber climbing sole. And now, all these years later, Vibram stepped onto the Paris Fashion Week stage, unveiling its showroom to showcase the groundbreaking sole technology that has made it a leader in high-performance footwear. As part of the event, Vibram hosted a viewing of their collaborations, including brands like Hoka, ROA, Nike, and Arc’teryx, and a community run in partnership with Kailas, where participants hit the streets to test a next-generation ultra-trail running shoe, putting Vibram’s cutting-edge soles to the test.

To mark the event, Schön! sits down — and tries on a pair of shoes — with Pietro Urbani who handles collaborations and projects at Vibram, to discuss adapting designs, forthcoming collabs, and more.

How would you describe Vibram?

Vibram is the best ingredient brand for the bottom of trail shoes. We want to push our perception as a brand that brings more than just being a supplier. Our core is technology, and we provide value through testing and performance assurance, not just putting a Vibram sole on a shoe. We ensure every product delivers on our promise of performance, technology, and lightness. There’s a real aesthetic to Vibram—it’s instantly recognizable, even on another design.

Yeah, the yellow Vibram logo.

Exactly. Even in fashion, we aim for top performance for each segment. For instance, with Moncler, it was about making the sole perform aesthetically and functionally. Working across different offices, like LA and Shanghai, we adapt to various design sensibilities. The performance is consistent, but the design sensibilities differ between Chinese, European, and American brands. These are very fashion-focused. It’s like how fabric, like cotton-poly blends, can have subtle differences in texture—minor chemical differences lead to different properties. For testing, we simplify the design, using a repeating pattern on a sheet, which we die-cut for templates. This way, we can test soles and compounds without making full shoes, which saves time and resources.

If a company wants to work with us but hasn’t developed their midsole or upper, we use this method to give quick feedback. For example, the sole on your feet right now features Megagrip, our pinnacle trail running compound. It’s known for excellent grip and durability—kind of a unicorn in the industry. While most soft grips wear out quickly, ours balances both.

It doesn’t look like a typical sole visually.

Right, but on a micro-level, the rubber conforms to surfaces for a mechanical lock, like gears meshing. That’s why it excels on wet terrain—it bonds and locks with rough surfaces.

They almost remind me of military shoes.

We work with the military as well, focusing on durability and grip. You’ll feel controlled slides rather than sudden slipping. We also create compounds for specific environments, like hiking in sand or wet surfaces for boating. Grip refers to rubber’s surface connection, while traction relates to lug design. Traction is like a rake—lugs grab the surface to propel you forward. Our teams in Italy and China advise brands on design adjustments, ensuring everything works as intended.

How do you plan collaborations? The collaborations seem extensive?

Really extensive. These are all collaborations in the sense that we worked with a brand to make the outsole. The technology on the bottom of each of these shoes represents the ten trail running shoes that performed best during the past year. They’re all already on the market, and we thought they were great shoes to display—maybe they won competitions, like Hoka. They took first and second place at UTMB (Ultra-Trail du Mont-Blanc). Then there’s a Chinese brand you might not know because it’s huge in China but just starting in Europe. Another brand makes pyramid underwear. We collaborated with them, creating an EVA cage for the bottom of the shoe. It’s cool because inside the cage, they put squares, like T-boxes, so it’s super soft. Without the cage, the shoe would fall apart on the first rock—it’s a way to protect the material.

What are the challenges in adapting something versatile to a design that’s even more versatile?

Usually, we collaborate with brands on outsoles. They might give us designs or share knowledge on how to position the lugs or design the outsole. It depends—sometimes it’s more collaborative, and other times, we handle it ourselves. For example, we work closely with the testing team in Boston. They test every single shoe, not just ours. When we work with a brand, we give feedback during the design phase, saying things like, “There’s too much empty space.” After the design review and sampling, we conduct a thorough testing process. It takes time, but for us, it’s crucial to provide detailed feedback before the product goes to market. That way, we can say, “This is approved by us,” and ensure it meets the performance standards we promise.

Learn more about Vibram at vibram.com.

interview. Patrick Clark