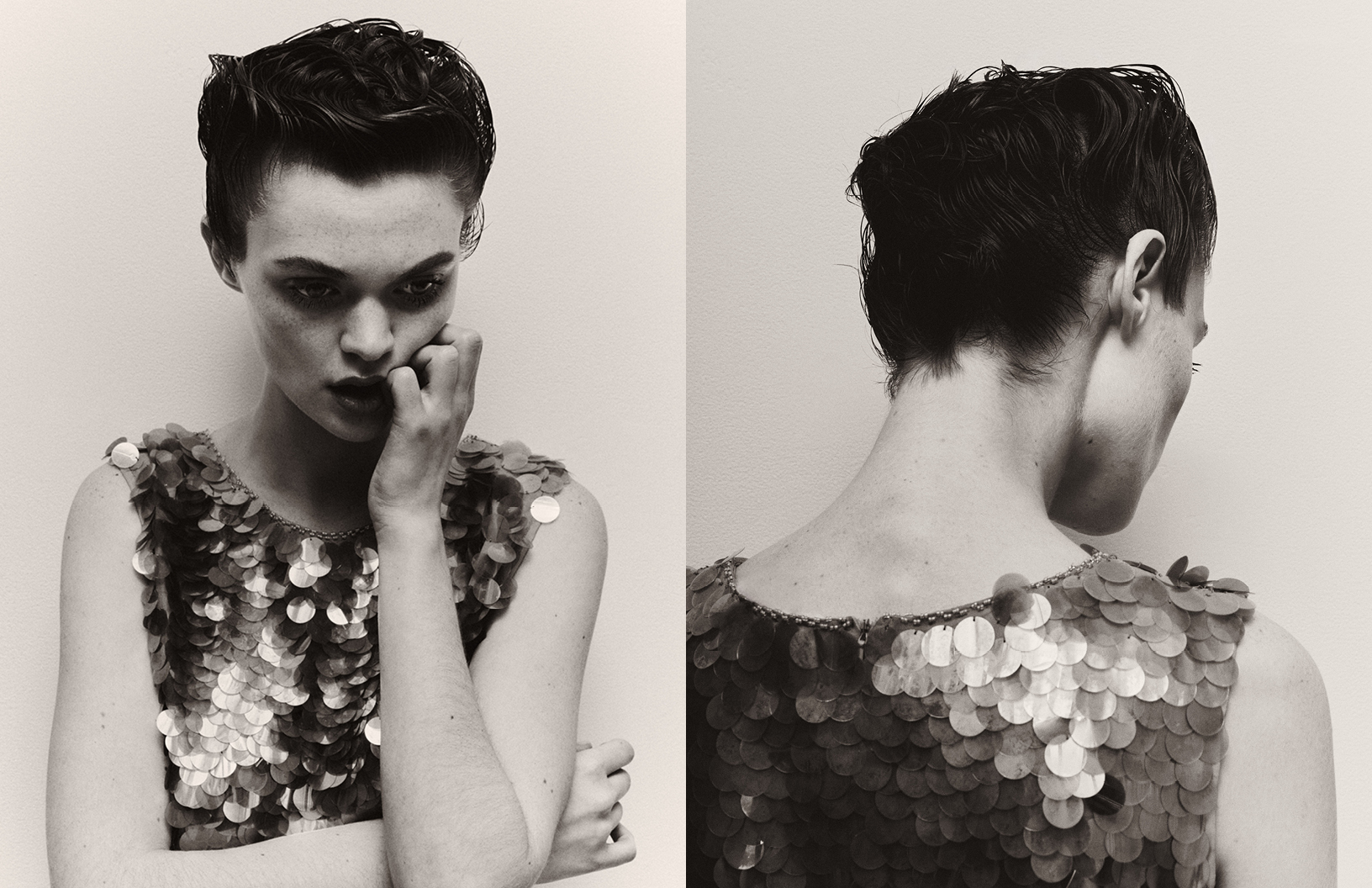

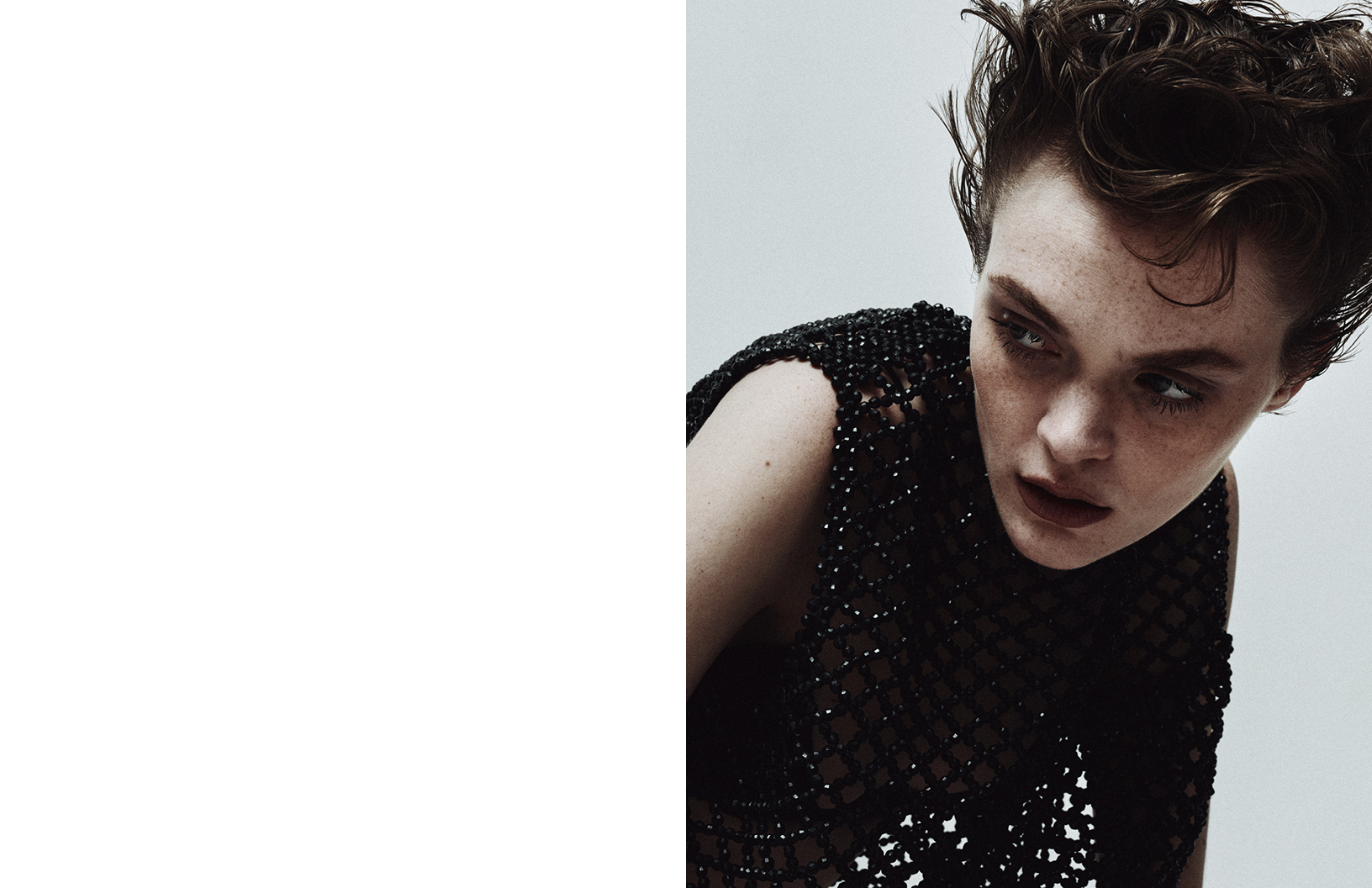

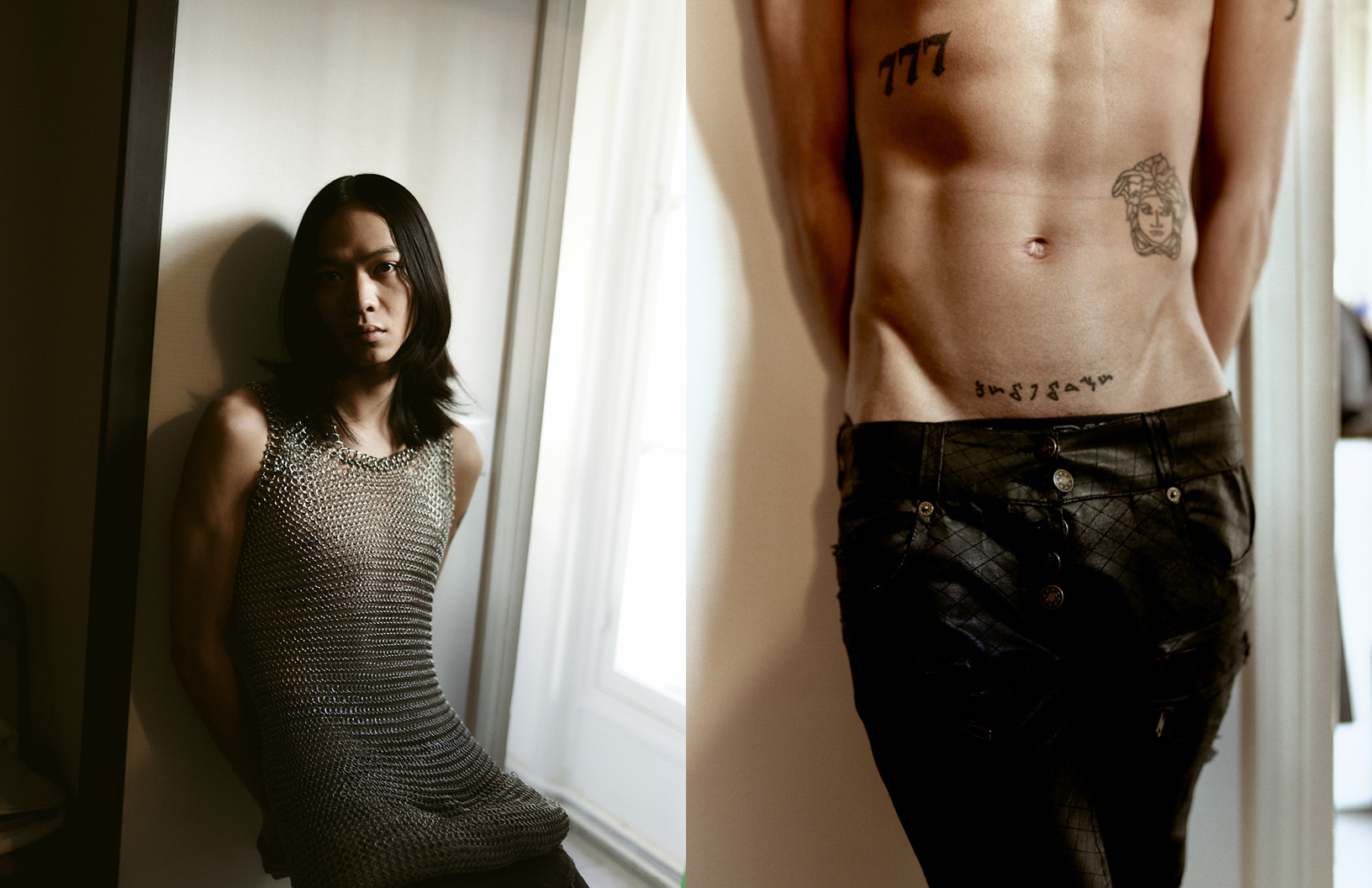

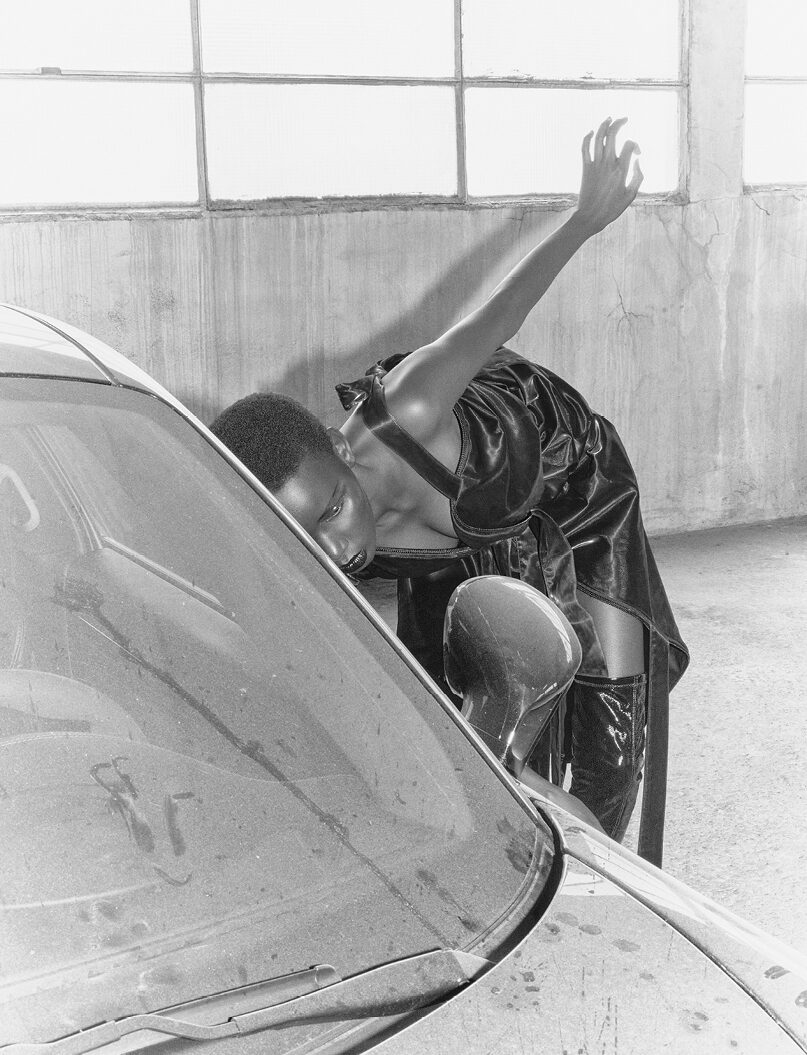

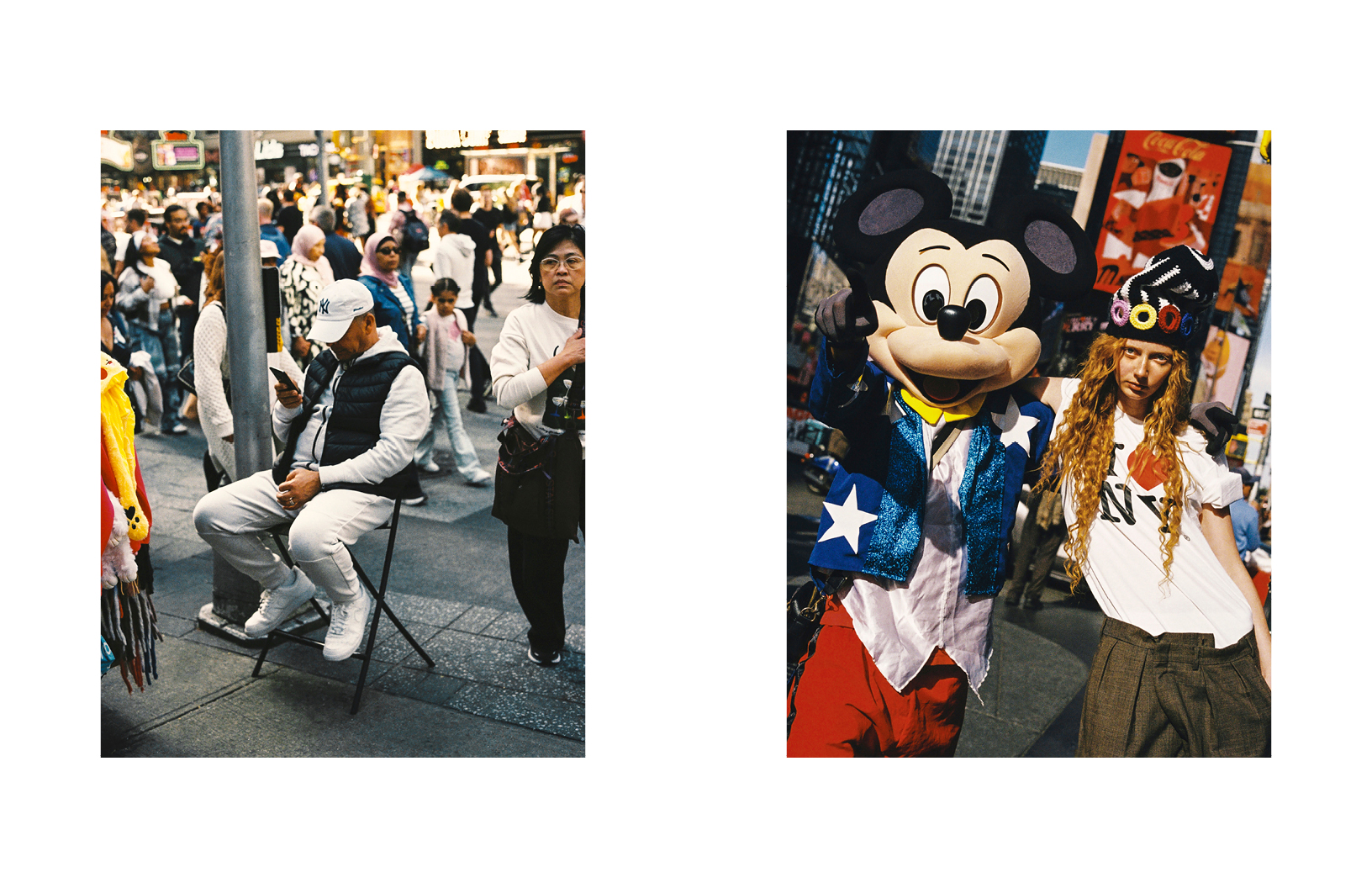

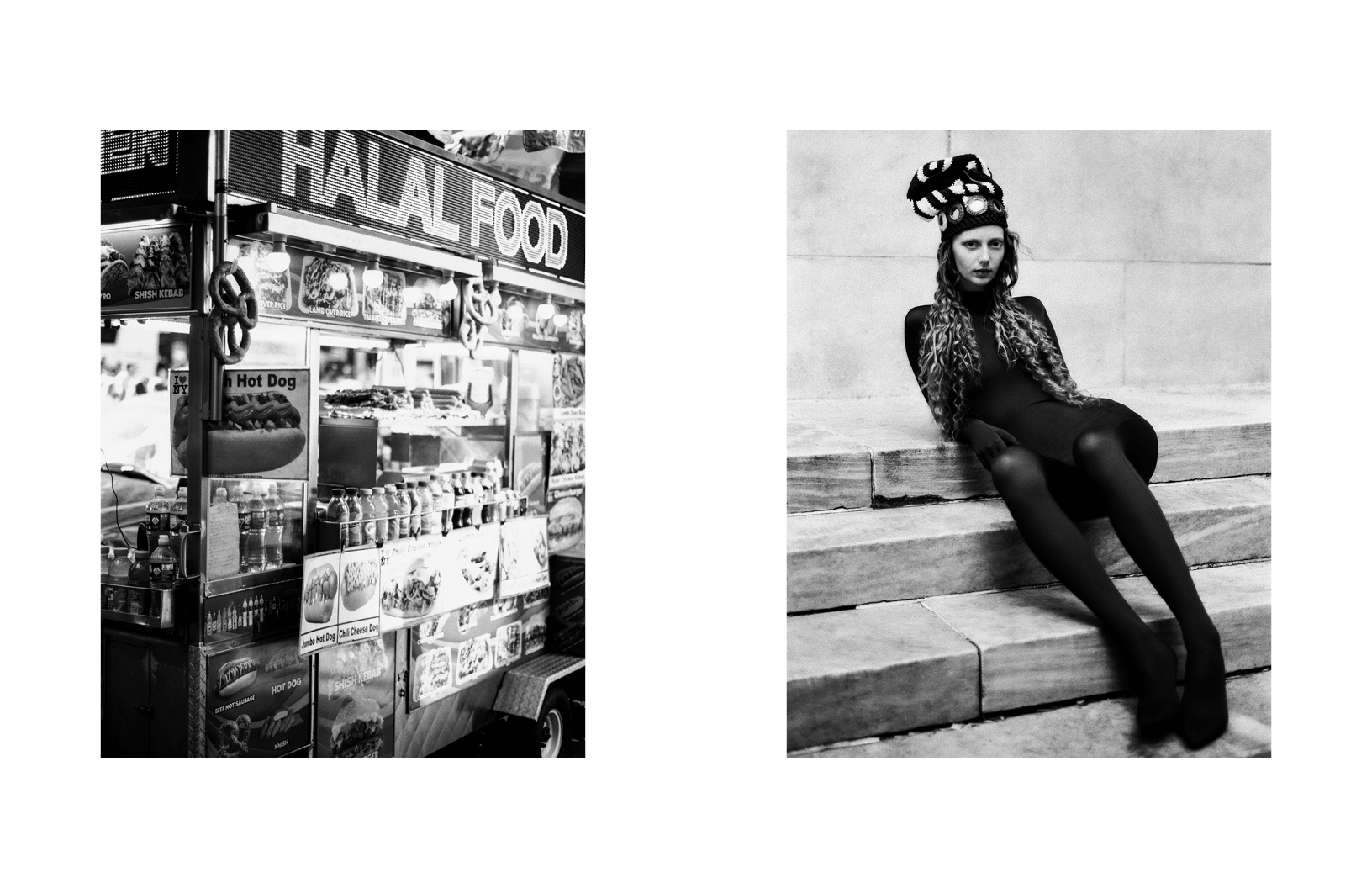

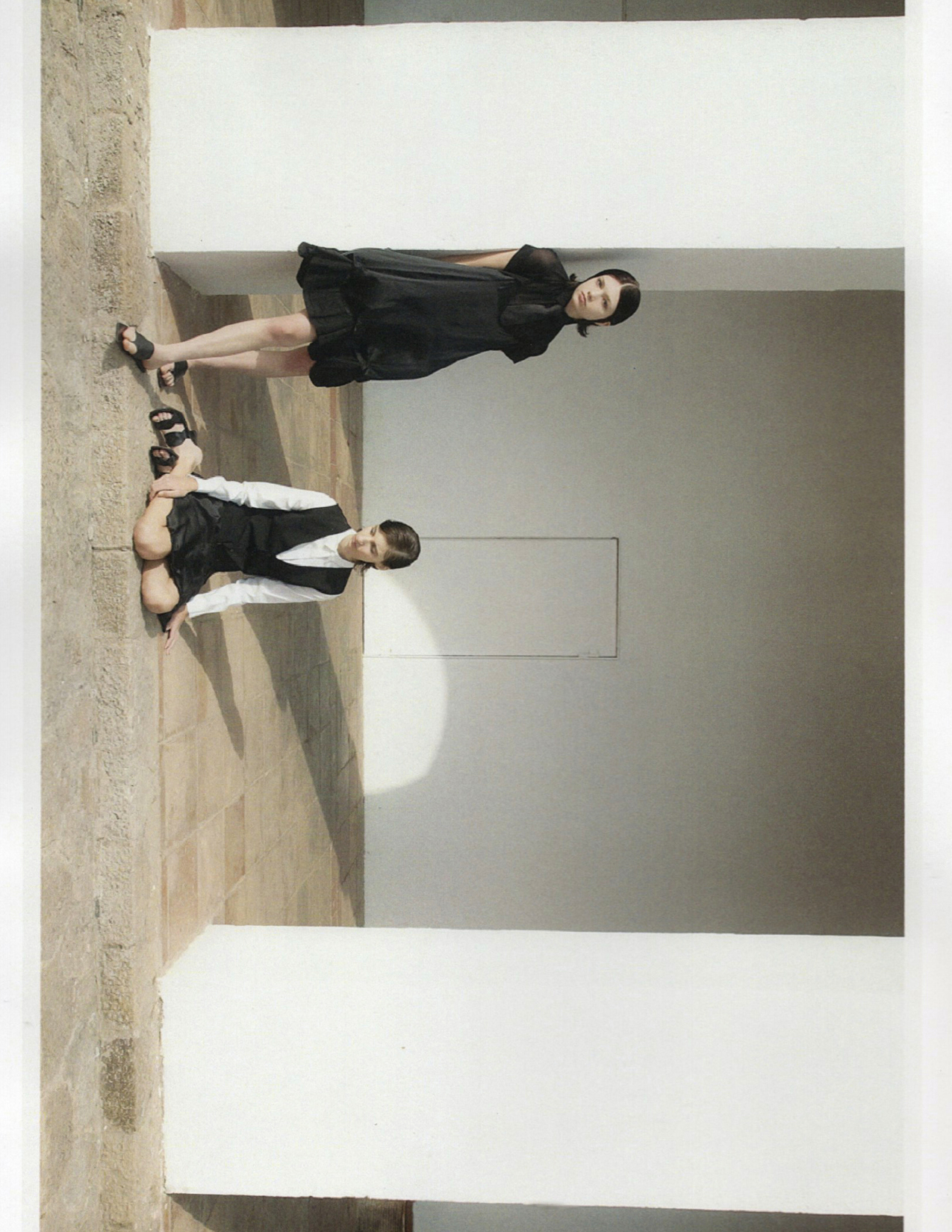

Photography | Preton Ubranco

Each year, countless fashion students graduate from Europe’s prestigious design schools. The MODAPORTUGAL LINKS competition selects a handful each from several institutions and brings them to Porto, where they get to show their garments on the catwalk to an international crowd, and where some of them go on to win prizes at a gala dinner at the stunning Palácio da Bolsa.

But this imitative is not simply about showcasing and rewarding emerging talent. The fledgling designers are first treated to private tours of the textile and garment factories located in the hills outside of the city, thus giving them a valuable insight into production practices. They are also invited to lunches and dinners where they network with the international press invitees.

The factories toured during the latest edition, which took place earlier this month, included Calvelex, Polopiqué and Riopele. Since we last visited factories with MODAPORTUGAL six years ago, we noticed that there has been an increased emphasis on addressing environmental concerns. For example, many of the sites have installed vast swathes of solar panels to help meet their energy needs.

Students visit Valérius 360 Recycling Centre. Photography | Dulce Daniel

At Polopiqué, we got to see what large-scale production looks like. The Polopiqué Group’s clients include high street giants, and it handles everything from spinning (4 million kgs of yarn a year), to dyeing, weaving and finishing of both woven and knitted fabrics. After a tour of Riopele, the students took part in a quiz, and those with the highest score (the participants from LCF) walked away with several rolls of fabric.

Calvalex provides end-to-end solutions for its 100 or so clients, from sourcing to manufacturing to stockholding and delivery. What was especially exciting for the students though was the company’s scheme fabrics4fashion, which is the largest fabric library in the world.

Not only are there inexpensive swatches, a student discount and international shipping but, most importantly for emerging designers, no minimum order. Yes, that’s right, orders start at just one metre, with a catalogue of over 20,000 references and 7,500 fabrics that are ready to go. The students visited the fabrics4fashion showroom and several walked away with cloth for their future collections. As well as being an invaluable source for small-scale companies and designers, it’s a great way to reduce waste as remnants are also available.

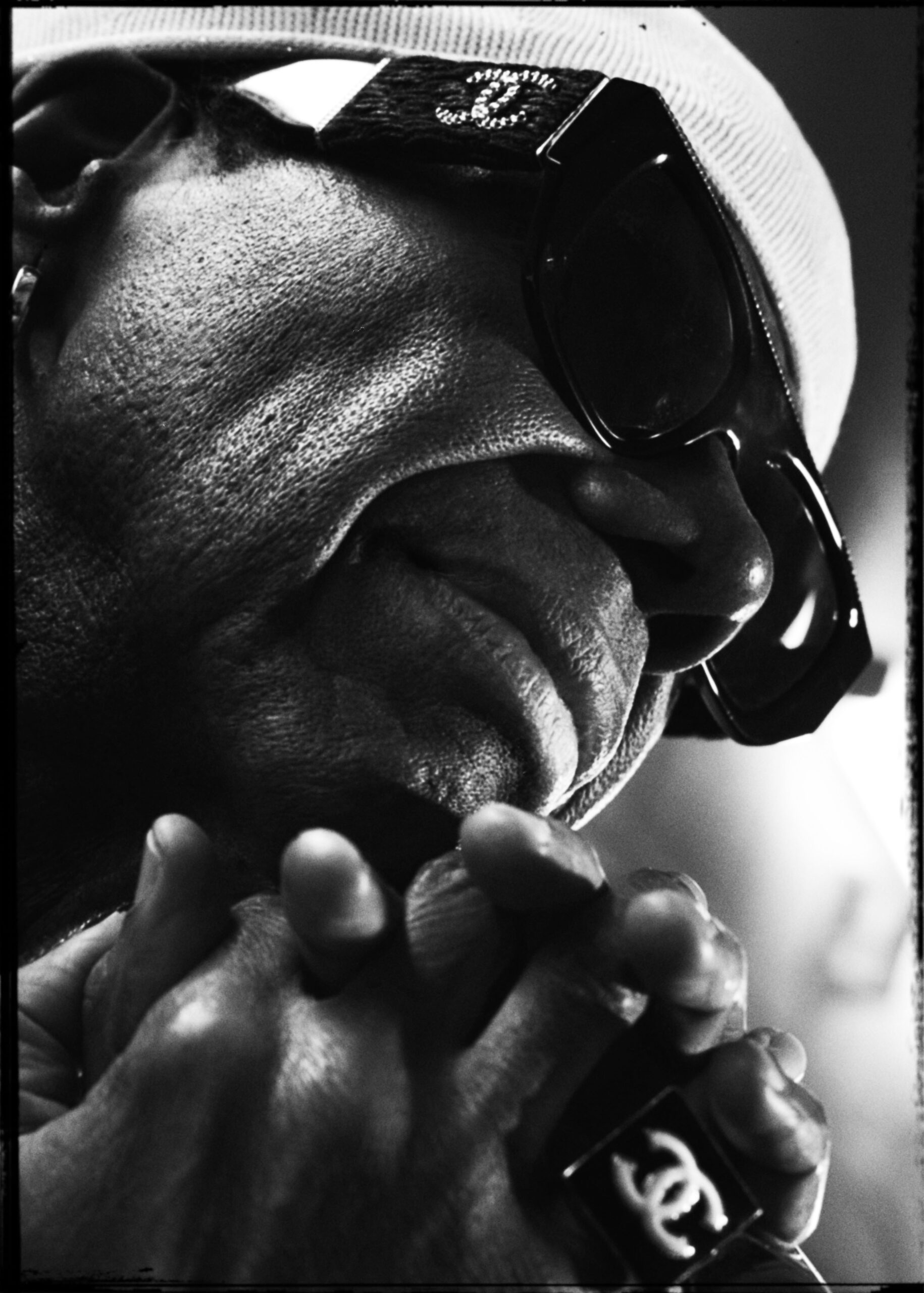

Valérius 360. Photography | Dulce Daniel

We were highly impressed by the Valérius 360 Recycling Centre. Established in 2017, the Valérius 360 project aims to implement a circular fashion model. Off cuts of jersey fabrics – either from its own manufacturing facilities or those of its many partner brands – are sent to the centre, where it is turned into fabrics and garments or – for the waste that can’t be transformed into textiles – cotton paper. To give you an idea of the impact of this, the company says that the production of just one of their 360 t-shirts saves between 722 and 1,400 litres of water compared to one made with conventional cotton.

Valérius 360 is already implementing other sustainable practices including the installation of solar panels and using the most energy efficient LED lights on the market, but it has high hopes for the future, such as removing chemicals and water entirely from the process. It aims to produce 70% of its energy from green sources and bring its carbon footprint to zero.

Once the young designers had explored the factories, it was time for the competition. There were 18 participants from six schools and the panel comprised judges from each of the students’ countries. One designer from each school took away a prize: Neža Simčič from Aalto University in Finland; Carla Mignano from Institut Français de la Mode; Ian Morris McDonald from Polimoda in Italy; Maria Nunes from Modatex Porto; Maxence Guenin from Head Genève and Eden Sherry from London College of Fashion. The judges had a tough time choosing the winner for Best Collection, but the grand prize went to Maxence Guenin.

“The winners were chosen for their aesthetic identity, conceptual relevance and impeccable technique,” says MODAPORTUGAL. “The jury looked for projects with real relevance to the contemporary fashion system.”

By supporting these young talents and connecting them with manufacturers, MODAPORTUGAL aims to strengthen the ties between the creative and productive sectors and to boost both Portuguese and European fashion in “an increasingly demanding global market”. And, who knows, perhaps some of these fresh faces might become the future clients of Portugal’s formidable textile industry.

MODAPORTUGAL LINKS is part of the Lusitano Project, supported by the PRR – _Recovery and Resilience Plan, and by the Next Generation EU European Funds.

Read more about MODAPORTUGAL here.

words. Huma Humayun

catwalk photography. Preton Ubranko

backstage photography. Luís Miguel Fonseca

factory photography. Dulce Daniel

images. Courtesy of MODAPORTUGAL