In his Milanese studio, where tradition and technology seem to collide, Felipe Fiallo is holding up a sneaker that looks as if it’s been plucked from the future: a crystalline structure glinting under the lights tinted in a vibrant red, the kind of shoe that demands a double take to fully understand its design. Next, the Co-Founder & Creative Director shows me a pair covered in different layers of breathable meshes, adorned with colourful regenerative plastic that hug the feet. These are only a few examples of the many innovative pieces from the Italian-Ecuadorian footwear brand, and the beginning of his market revolution.

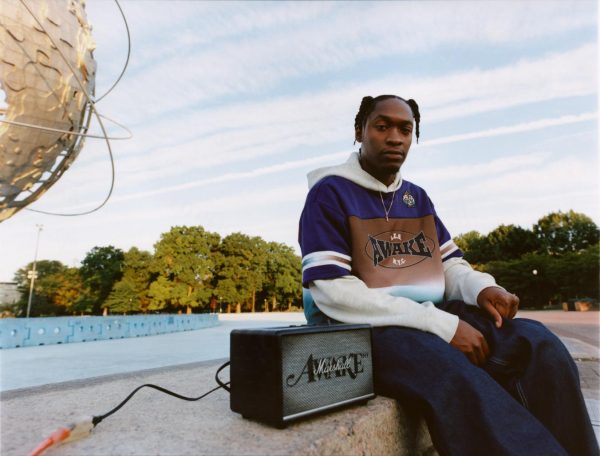

“The beautiful thing about fashion is that it’s a cultural element,” says Fiallo. “Footwear is the perfect match between engineering and art. It has to be extremely performative, but also an element of identity. After so many years in a saturated market, identity is more important than ever.”

Fiallo’s journey has been anything but linear so far. Born in Ecuador, trained as an industrial designer and architect, he designed the Luxury Train of Ecuador before turning his attention to fashion. “I’ve always worked through material innovation and technical projects,” he recalls. “But in 2018, I switched to fashion to build, not just to understand that the product has to be functional, but that it can transform behaviours in the consumer and the human. Footwear, for me, is the thing that lets you walk into the future.”

Now, Fiallo’s approach is a perfect blend of science and style. His collaborations with Adidas MakerLab and MIT, and his early adoption of 3D printing in footwear, set him apart. “In 2019, I proposed a fully 3D-printed shoe. Now everybody’s doing it, but back then, people would say, ‘What is that?’ I was creating 3D renders and people told me, ‘That’s not fashion.’ But I knew people needed to see it first, and then they’d start appreciating it.”

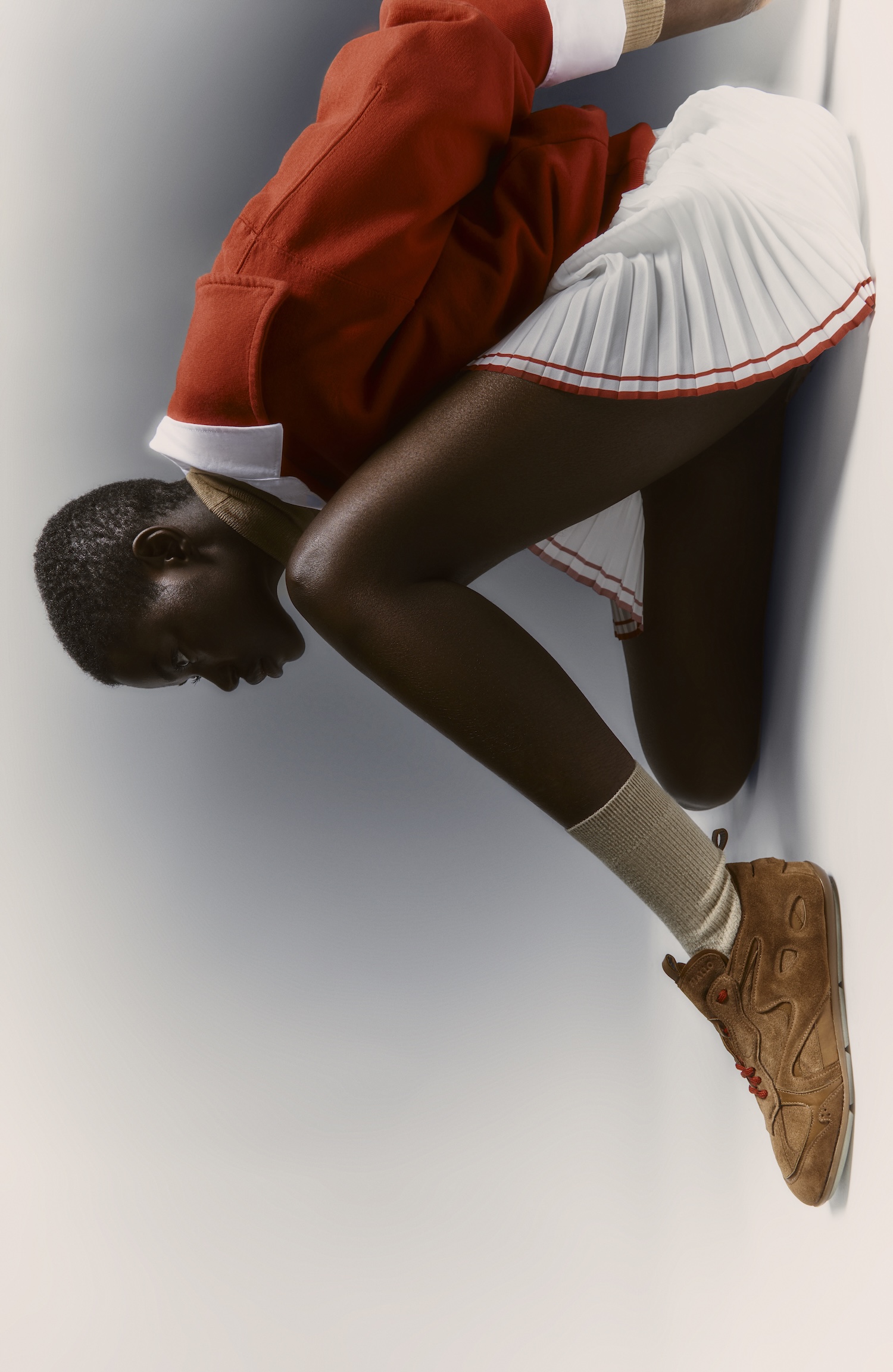

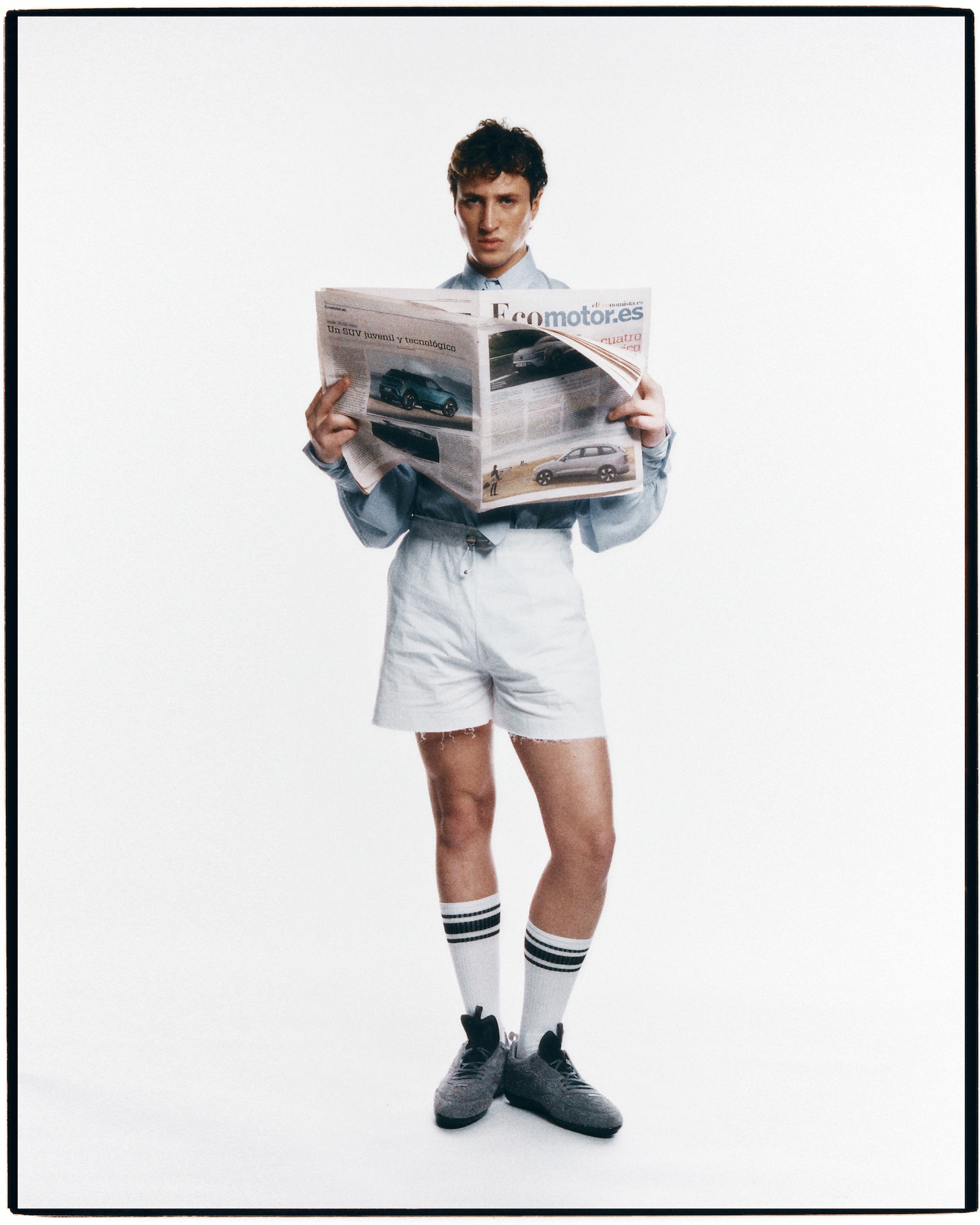

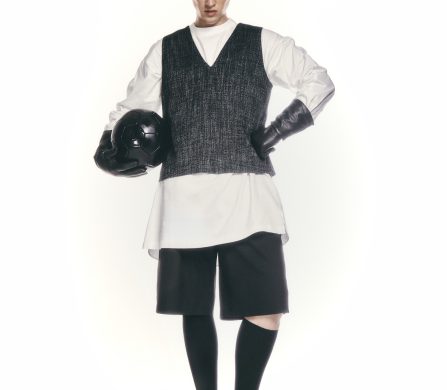

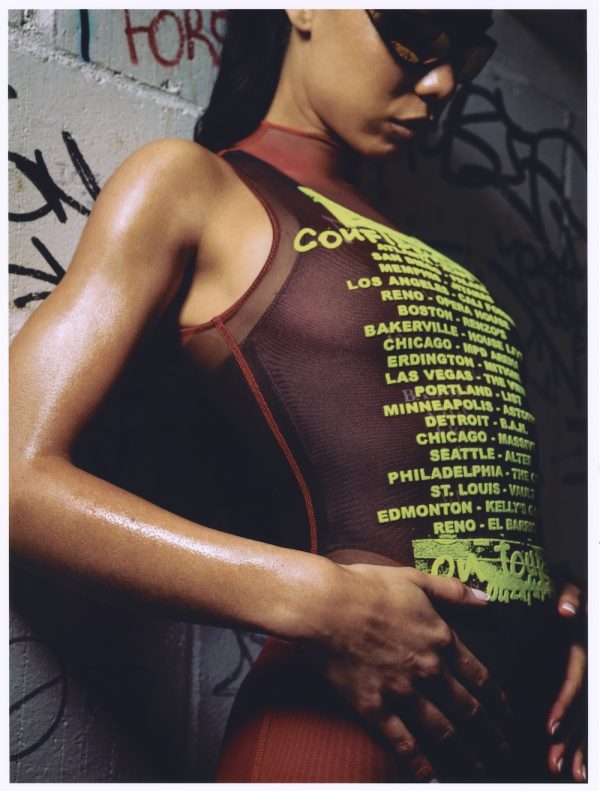

The new SS26 collection, Victory, is a love letter to motorsport and the golden age of Formula 1. “Victory is a collection of optimism, of travelling, of moving,” Fiallo says. “After so much chaos and uncertainty, I think there’s a new time. This is a collection for the full day — for the journey, for the celebration, for hope.”

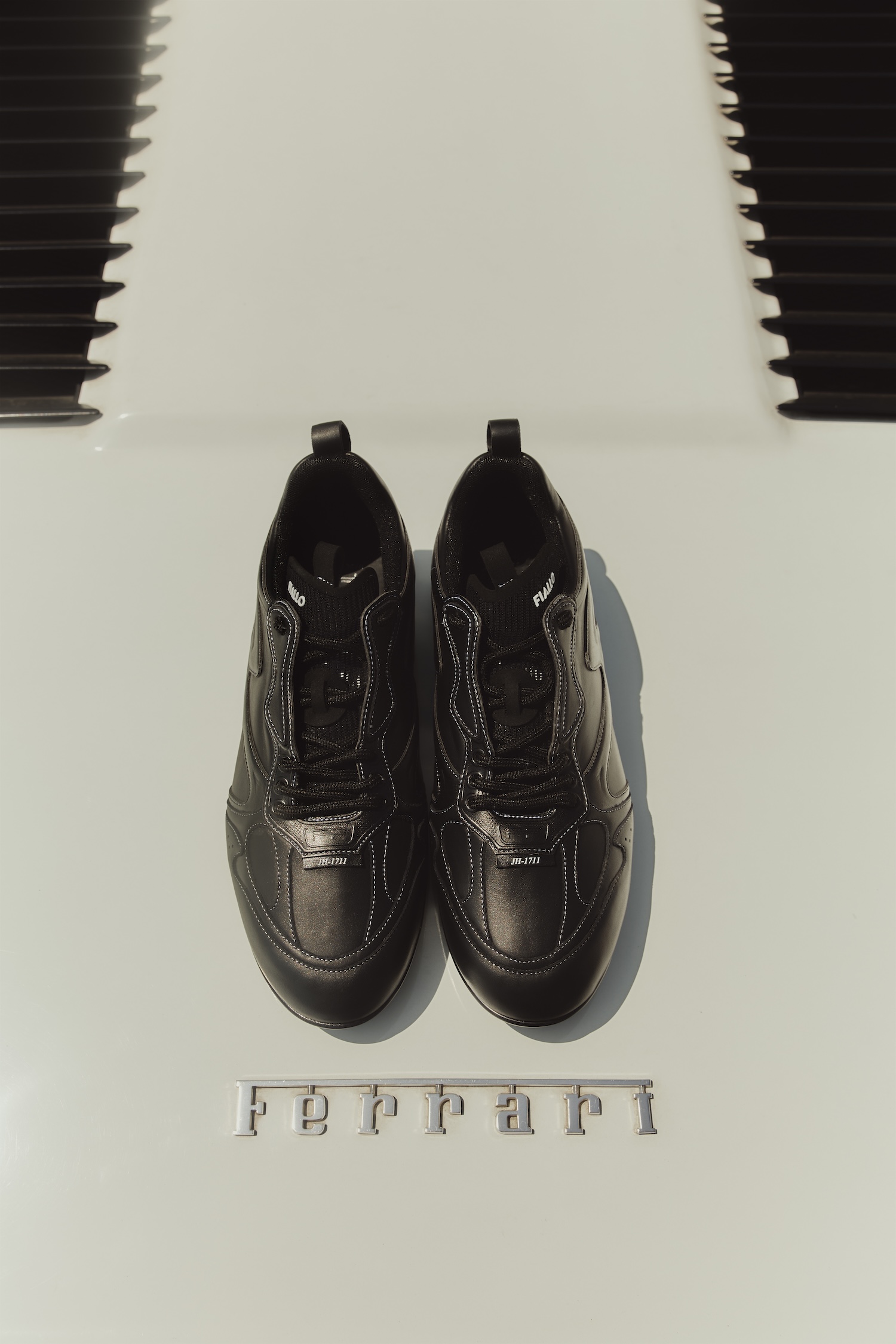

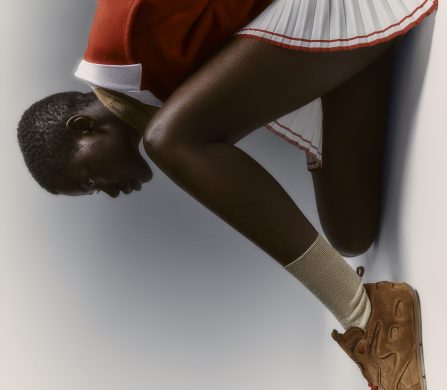

The shoes themselves are technical marvels: a hidden 1.2cm heel, exoskeleton structures, and a silhouette inspired by the original 1963 Car Shoe. Originally invented by Gianni Mostile for motorsport elites and the jet set, this classic model is reimagined for a new era. “We wanted to create a new silhouette, inspired by the traditional car shoe, but fully flat with a hidden heel for comfort and posture. The outsole and insole are engineered to support the arch and cushion the heel — so you can drive, walk, and celebrate.”

What sets Fiallo’s relationship with the automotive world apart is its depth. SS26 also marks the brand’s official entry into motorsport, debuting with a capsule collection in collaboration with Double TT Racing with Ferrari. “We’re not following trends, but detecting what’s only just being made,” he explains. “We’ve signed a collaboration with the team, and each pilot will have the chance to customise their own tag, to bring their message, their pain, their victory.” The collection is as much about storytelling as it is about speed: “It’s about bringing back the time of celebration and travel, the hope that comes with movement.”

Fiallo embraces the retro-futuristic aspect of his shoes wholeheartedly. “It’s about the perfect match between past and future: classic silhouettes with innovative materials and techniques. We combine calf leather with technical fabrics, transparent materials, and even crystals that grow directly onto the sneaker. No glue, no stitching — just biology and human ingenuity.”

When it comes to sustainability, Fiallo doesn’t treat it as a buzzword. For him, it’s a non-negotiable part of how things should be made: honest, regenerative, and future-focused. “We don’t pray for sustainability. We create for us, for the planet. The concept is not recycling, but regenerative design,” he says. “Our TPU is fully regenerative; the digital print is 97% water-based. This shoe can be recycled in a year, three months — again and again. That’s the real regenerative material.” Every pair also comes embedded with a digital passport, ensuring full traceability from raw material to final stitch.

His Ecuadorian heritage feels intertwined into every pair. “I’m lucky enough to come from one of the richest places in the world — Ecuador. My DNA is nature. My family built railways, my grandfather was mayor of Quito. Engineering is in my heritage, and I bring that spirit to fashion. Fiallo is about combining the Latin American spirit with Made in Italy craftsmanship.”

That hybrid perspective quickly made waves. Before he’d even launched a full collection, Fiallo won ITS Ferragamo Prize for Most Innovative Designer back in 2020. “It was a super honour. I was working in front of 15,000 shoes built by Salvatore Ferragamo. I saw a big gap in the luxury industry to create something that combined performance and elevated style.”

Although he’s not keeping that knowledge to himself. Education is a key part of Fiallo’s mission. “It’s fundamental to inspire others, to show that it’s possible to do things differently. There’s a lot of jealousy and borders in the industry, but not everything is bad. My commitment is to spread the good news: fashion has a lot of space for renovation. Creativity has the power to change the rules.”

So, where does he see luxury footwear heading? “We’re not here for a season. We’re building a heritage. We want to become the first company to reduce 1% of the planet’s damage through regeneration. Our consumers receive an NFT tag — a keyholder to the community and to planet regeneration. For us, it’s about biology, digitalisation, couture — a new standard we call ‘bio-digital couture.’”

And while the future of luxury may still be evolving, Fiallo has a clear vision for what Made in Italy can become. “We call it Made in Italy 2.0 — a combination of traditional craftsmanship and new technologies,” he says. True to that ethos, the brand’s production spans the country, with factories in Florence handling manufacturing and partners in the south producing the packaging. “Factories told me, ‘Felipe, you’re crazy, you can’t do this in Italy.’ But we did. We’re pushing the boundaries, keeping the heritage, and giving the new generation a reason to desire, to walk into the future.”

As the conversation wraps, Fiallo’s optimism is infectious. “This is how we celebrate self — the real victory. To bring this to a new generation, to our community, is our biggest win.”

Discover the collection here.

photography. Alejandro Arrias, David Bravo Busto

words. Gennaro Costanzo