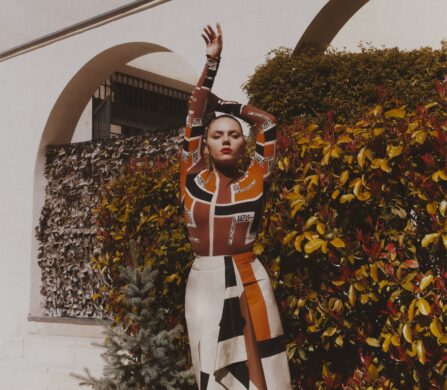

When durable materials and craftsmanship come together, the result is pure elegance. With Loro Piana linen garments, there is a certain ‘savoir-faire’ interwoven through each piece — specifically due to the linen used. Linen is a noble fibre that evokes effortless elegance, infinite freshness, and impalpable softness — sumptuous and pleasant to the touch, it offers unparalleled versatility.

Linen exemplifies the Maison’s dedication to transforming the finest yarns into fabrics that reflect unparalleled craftsmanship, timeless elegance, and a distinctive feel. As part of their linen traceability campaign, which focuses on the environmental aspects of linen production and sustainability, Loro Piana is giving fashion lovers a transparent insight into what goes into the crafting of their favourite pieces. For 150 years, the Solbiati factory has been a leader in linen production and, since 2013, an integral part of Loro Piana. The Maison’s artisans have extraordinary expertise, enabling them to create unique textures by blending linen with luxurious cashmere, silk, and wool, thereby altering the fabric’s structure, appearance, and touch. Combining linen with cashmere merges the breathability and crispness of linen with the softness and warmth of cashmere, making it ideal for all seasons.

Loro Piana’s linen is certified by Masters of Linen, guaranteeing it is 100% made in Europe, from flax field to finished garment. Linen is inherently more sustainable than other crops, requiring less water and pesticides because it is grown without irrigation. It is also naturally antibacterial, anti-pilling, highly breathable, and effectively absorbs humidity. The Maison and its flax growers are committed to upholding the highest standards of quality, transparency, and local production. The process of turning the naturally rigid flax stem into fine, comfortable linen fibers are meticulous, giving the garments the Loro Piana signature touch.

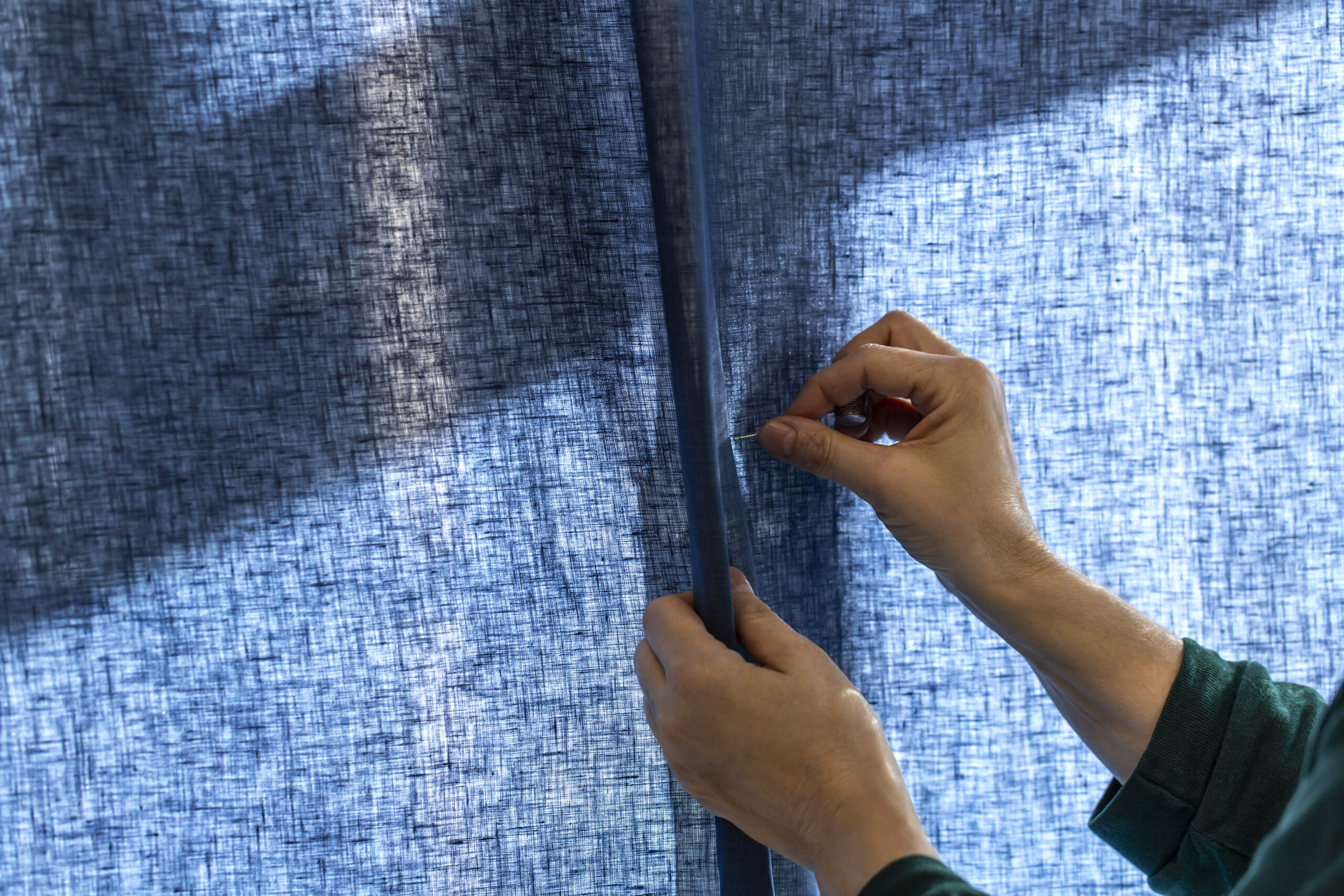

From the humid regions of Normandy in France and Belgium, renowned for producing the finest linen, the selection of fibres is an intricate experience; done by an expert by sight and touch. Harvesting, drying, and hand-detaching are all parts of the beginning stages of creating linen. Traditional methods use manual techniques, where craftsmen hand-detach the fibres, preserving their integrity and purity. This artisanal approach ensures superior linen quality and honours ancient textile craftsmanship traditions. The next phase, combing, separates the long fibres from the short ones, aligns them, and prepares them for spinning. Once the ribbon is created, it is spun into a thread. Expert artisans inspect and adjust each strand, ensuring uniformity and precision. Skilled spinners then transform the fibres, and with each spindle twist, linen becomes yarns of exceptional refinement. Loro Piana uses Nm110 linen threads, the finest available; one kilogram of this thread can stretch for 110 km.

Fabric creation occurs in the Maison’s factory, where warping and weaving demand attention to detail and precise craftsmanship. Linen can be treated with aloe vera during finishing, adding antibacterial and moisture-wicking properties, and infusing the fabric with softness for Loro Piana’s signature touch. What sets the Maison’s linen apart is its extensive research for exceptional raw materials, the use of the finest yarns, and innovative blends and finishes.

Learn more at loropiana.co.uk.